Metal Studwork has emerged as an essential component in modern construction and renovation projects. This innovative framework provides a sturdy and reliable alternative to traditional wood framing, gaining popularity due to its numerous advantages. In this introduction, we will explore what metal studwork entails, its key benefits, and its various applications within the building industry.

Constructed from steel, metal studwork offers durability, fire resistance, and resistance to pests, making it a preferred choice for both commercial and residential projects. Its lightweight nature allows for easier handling and installation, contributing to overall project efficiency. Additionally, metal studwork accommodates various design elements and can easily be integrated with other building materials, making it highly versatile.

As we delve deeper into this guide, we will cover the installation process step-by-step, highlighting best practices that ensure a successful implementation. Understanding metal studwork not only enhances project outcomes but also equips builders and DIY enthusiasts with the knowledge to utilize this framework effectively. With its rising significance in the industry, now is the perfect time to explore the benefits and practical uses of metal studwork in contemporary construction.

Metal studwork is a construction method that utilizes metal studs instead of traditional wood framing for creating walls and partitions. Typically made from galvanized steel, metal studs are lightweight yet strong, making them an excellent choice for various applications, including residential, commercial, and industrial projects. This approach provides greater stability and fire resistance compared to wood framing, which contributes to its growing popularity among builders and contractors.

One key advantage of metal studwork is its versatility in design and installation. Metal studs come in various sizes and can be easily cut and adjusted to fit different layouts. This flexibility allows for the creation of intricate wall systems, including curved walls and ceilings. Additionally, the non-combustible nature of metal studs enhances safety in areas where fire resistance is critical, such as in commercial buildings. The installation process is also streamlined, as metal studs can be quickly assembled using screws and connectors, significantly reducing construction time and labor costs.

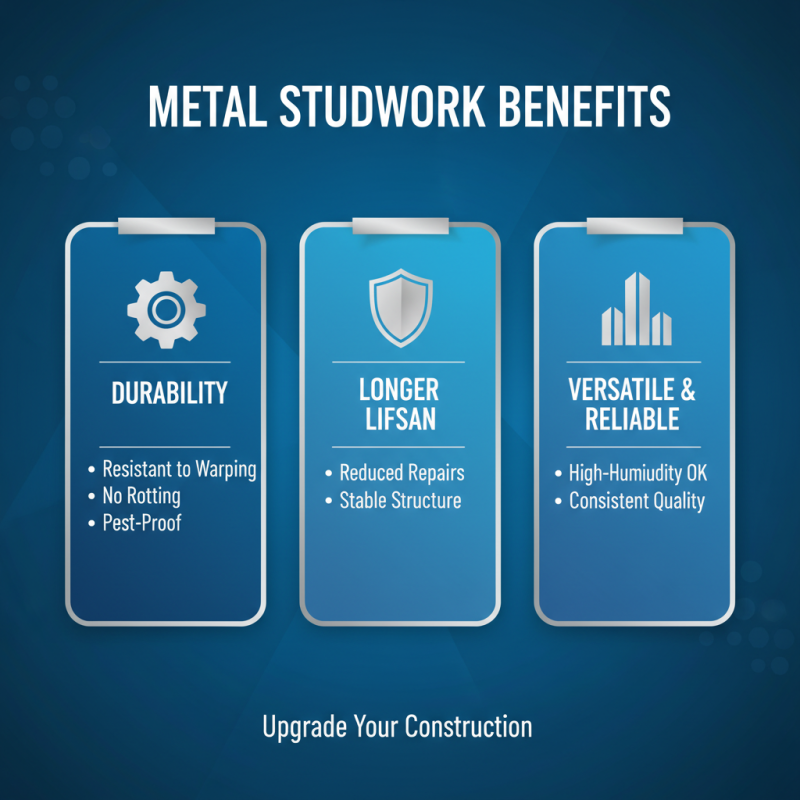

Metal studwork has gained significant popularity in construction due to its numerous advantages over traditional wood framing. One of the key benefits of using metal studs is their superior durability. Unlike wood, metal studs are resistant to warping, splitting, and rotting, making them an ideal choice for a variety of environments, particularly those with high humidity or pest-related concerns. This durability translates into a longer lifespan for structures, reducing the need for repairs and replacements over time.

Another important benefit is the ease of installation. Metal studs are lightweight and can be quickly assembled, which often results in shorter construction times. This efficiency is further enhanced by the precision with which metal studs can be cut and connected. Additionally, they provide excellent fire resistance, contributing to enhanced safety in building design. The ability to create non-combustible walls with metal studs is particularly valuable in commercial and industrial construction, where fire safety is paramount. Overall, these key benefits underscore the growing preference for metal studwork within the construction industry.

Metal studwork has become an essential component in modern construction, offering a versatile alternative to traditional wood framing. This lightweight material is widely utilized in various applications, including residential, commercial, and industrial projects. According to a report by the Metal Framing Alliance, the metal studs market is projected to grow at a compound annual growth rate (CAGR) of over 6% from 2021 to 2028, highlighting the increasing preference for metal stud frameworks.

One of the most common applications of metal studwork is in the construction of interior walls and partitions. This method allows for greater flexibility in design, enabling builders to create spaces that can easily adapt to changing needs. Additionally, metal studwork is impervious to pests, such as termites, and is resistant to warping and shrinking, which can often compromise the structural integrity of wooden frameworks. The National Association of Home Builders indicates that over 40% of new homes are now constructed using metal stud systems, showcasing a significant shift in building practices.

Furthermore, metal studwork is frequently used in commercial construction for its ability to support heavier loads and its fire-resistant properties. These features make it ideal for schools, hospitals, and office buildings, where safety and durability are paramount. Data from the U.S. Bureau of Labor Statistics reveals that construction projects utilizing metal studwork experience a reduction in overall labor costs, which can be attributed to the quicker installation times compared to traditional building methods. This efficiency, coupled with the material’s longevity, solidifies metal studwork as a top choice for both contractors and architects in today’s evolving construction landscape.

The installation of metal studs involves several key steps that ensure a strong and reliable framework for your construction project. Begin by gathering the necessary tools and materials, including metal studs, screws, a level, and a measuring tape. Start by marking the layout of your walls on the floor and ceiling using chalk lines. This initial step is crucial, as it serves as a visual guide for where the metal studs will be placed.

Next, cut the metal studs to the desired lengths, taking care to measure accurately to avoid waste. Secure the bottom track to the floor using screws, making sure it is level. Following this, attach the top track to the ceiling in alignment with your marked lines. Once both tracks are in place, insert the vertical metal studs into the tracks and secure them with screws. Ensure the studs are spaced appropriately, typically 16 or 24 inches apart, depending on your project’s requirements. Use a level to guarantee that everything is straight before finalizing the installation.

Finally, after all the studs are secured, check for stability and adjust if necessary. Once satisfied, you can proceed with adding wallboard or other finishing materials. This systematic approach to installing metal studs helps create a robust framework that is capable of supporting a variety of finishes, making it an excellent choice for modern construction projects.

Maintaining metal stud structures is essential for ensuring their longevity and structural integrity. These structures, commonly used in both residential and commercial settings, can withstand various environmental factors, but regular maintenance is key to preventing issues over time.

One important tip is to routinely inspect the metal studs for any signs of corrosion or rust, especially in areas where moisture may accumulate. If you notice any rust spots, they should be treated immediately with a rust-inhibiting primer and paint to prevent further deterioration. Additionally, sealing joints with appropriate caarlnts can help protect the studs from moisture penetration.

Another maintenance tip involves checking the overall alignment and stability of the metal studs. Over time, shifting or settling of the building can cause misalignment. Regularly verify that the studs are plumb and properly anchored. If you find any structural issues, it's advisable to consult with a professional to address the instability promptly, ensuring that your metal studwork remains sound and supportive for its intended purpose.