In recent years, the construction industry has increasingly adopted Steel Stud Framing for its unique advantages. According to a report by the National Steel Framing Alliance, the use of steel studs has grown by over 30% in commercial building projects since 2018. This trend highlights the material's significant role in modern construction practices.

Industry experts emphasize the benefits of Steel Stud Framing. John Smith, a leading architect in sustainable design, notes, "Steel stud framing provides durability and flexibility that traditional materials often lack." However, challenges remain. For instance, builders must consider thermal bridging when using steel, which can impact energy efficiency.

Securing a firm understanding of Steel Stud Framing is essential for construction professionals. Balancing innovation with practical application can drive project success. One must reflect on the limitations and consequences associated with this widely embraced method.

Steel stud framing is becoming increasingly popular in modern construction projects. This method offers

lightweight and durable structural support for walls and ceilings. Unlike traditional wood framing, steel studs resist

warping, twisting, and shrinking. They’re also non-combustible, which enhances fire safety in buildings.

A significant benefit of steel stud framing is its ease of installation. Builders can quickly assemble panels using screws and studs. However, the process isn't without

challenges. Accurate measurements are crucial; a small mistake can lead to misalignment. Additionally, working with steel requires

some specific tools and skills that not all contractors may possess.

Another advantage is minimal waste. Steel is often recycled, contributing to sustainable construction practices. Still, it's essential to reflect on the cost

implications of using steel. Although initial expenses may be higher, longevity often compensates for this. Understanding these factors can lead to

better decision-making when choosing materials for construction projects.

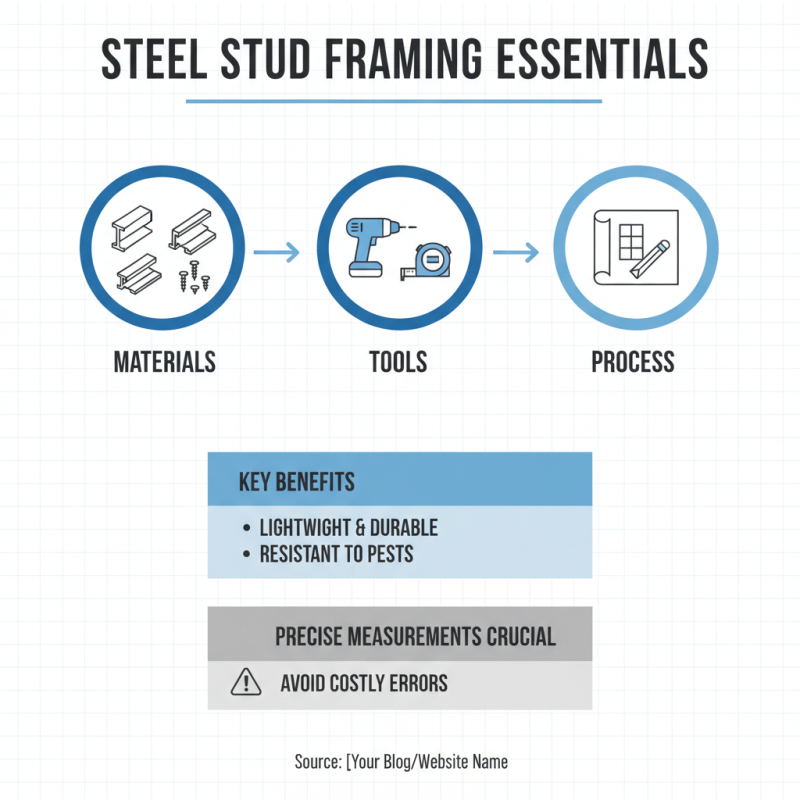

When planning to use steel stud framing, it's essential to gather the right materials. Steel studs are lightweight and durable, making them an excellent choice for various projects. You'll need steel studs, track, screws, and tools for installation. Keep in mind the importance of precise measurements. Miscalculations can lead to significant setbacks.

For those just starting, consider these tips. Always wear safety gear. Protective eyewear and gloves can prevent injuries. When cutting steel studs, a metal saw works best. A clean cut will make assembly much smoother.

Remember, not all projects go as planned. It's easy to overlook small details, like the spacing of the studs. If the spacing is incorrect, it can cause issues later on. Double-checking your work can save time and frustration. Keeping a detailed list of materials and procedures can help track your progress effectively.

Steel stud framing is becoming increasingly popular in construction. This method offers durability and versatility. Understanding how to install steel studs correctly is crucial for efficient projects.

Start by gathering the right tools. You’ll need a metal cutting saw, levels, and studs. Begin by marking the wall layout on the floor and ceiling. Accurate measurements are key. The Steel Framing Alliance reports that improper installation can lead to structural issues. Use a stud finder to locate existing structures. Ensure your layout is straight and precise.

When it’s time to install, secure the top and bottom tracks first. Then, insert the steel studs into the tracks. Ensure they are vertical and aligned. Use screws to fasten them in place. This step can be tricky; check your work often.

**Tip:** Always wear safety gear. Steel edges can be sharp. Also, consider using a laser level for better accuracy. It’s a small investment for a big improvement.

Don’t underestimate the importance of insulation. Steel framing can create thermal bridging. Adding insulation will help meet energy efficiency standards. An energy audit can provide insight into your project’s performance. This can save costs in the long run.

| Step | Description | Tools Needed | Estimated Time |

|---|---|---|---|

| 1 | Plan and Design the Layout | Measuring Tape, Graph Paper | 2 hours |

| 2 | Gather Materials | Steel Studs, Track, Fasteners | 1 hour |

| 3 | Install the Bottom Track | Drill, Level, Screws | 1 hour |

| 4 | Erect Vertical Steel Studs | Screw Gun, Square | 2 hours |

| 5 | Install the Top Track | Ladder, Screws | 1 hour |

| 6 | Add Horizontal Bracing | Measuring Tape, Saw | 1 hour |

| 7 | Install Insulation and Drywall | Drywall, Insulation, Knife | 3 hours |

Using steel studs in construction offers many benefits, but specific mistakes can hinder your project. One common error is failing to check dimensions accurately before cutting. Always double-check measurements. A small mistake may lead to significant setbacks.

Another frequent issue is neglecting the insulation. Steel conducts heat and cold, which can impact energy efficiency. If you don't insulate properly, costs will rise. Use high-quality insulation that fits well within the studs. This step is crucial.

Finally, not reinforcing joints can lead to structural weaknesses. Ensure that all connections are secure. Use appropriate fasteners and additional bracing where needed. Piece everything together carefully. Remember, precision is key. Small oversights can lead to bigger problems down the line.

When working with steel stud framing, finishing techniques play a crucial role. The seams of steel studs require careful attention. Applying joint compound helps create a smooth surface, but achieving perfection can be tricky. It's important to sand between coats, but over-sanding can lead to uneven areas.

Painting is another aspect that demands precision. Choosing the right primer is essential for good adhesion. A good finish starts with preparation. Often, steel studs can show through the paint if not properly sealed. It's a mistake that many make. The sheen of the paint can amplify imperfections. A flat finish may hide flaws better than a glossy one.

Texturing gives depth and style to the walls. Techniques like knockdown or slap brush add character. However, mastering these methods takes practice. Some may find their initial attempts less than satisfactory. Learning to adjust pressure and angle improves results. Each technique offers room for growth and creativity. Embrace the learning process in your projects.